Project Management

PSG takes great delight in our Project Management team. We strive to surpass our client’s expectations by performing as professional team players, dependable, enthusiastic and proactive. We are committed to continually improving procedures, practices, and the value of our service to our customers and to the construction industry.

Every project is assigned a project manager as contact for all stages / phases of the project from engineering, detailing, fabrication, erection, invoicing / accounting, and delivery. No matter how large the job, each project manager oversees all aspects of the job to make sure it is completed on time and on budget to the satisfaction of our customers.

From beginning to end, Pittsburgh Steel Group provides the project management support to make all projects a success.

.

.

Fabrication & Assembly

Pittsburgh Steel Group facility is equipped with the latest computer-aided detailing and fabricating systems, which allows information to be electronically processed from engineering and drafting directly to the shop floor. The initial cutting, drilling, punching, prepping, burning and other operations are performed with state-of-the-art processing machines utilizing CNC files downloaded directly from our 3D models.

Member Assembly - Once all fittings / small parts have been machined, PSG fitters and welders start transferring crucial dimensions from the fabrication drawings to the actual piece of steel. This information contains detail part marks, exact dimensions, and the necessary weld symbols used for final fabrication. This process requires skilled fitters and welders, many of whom have been working for PSG from the start.

.

.

Project Detailing

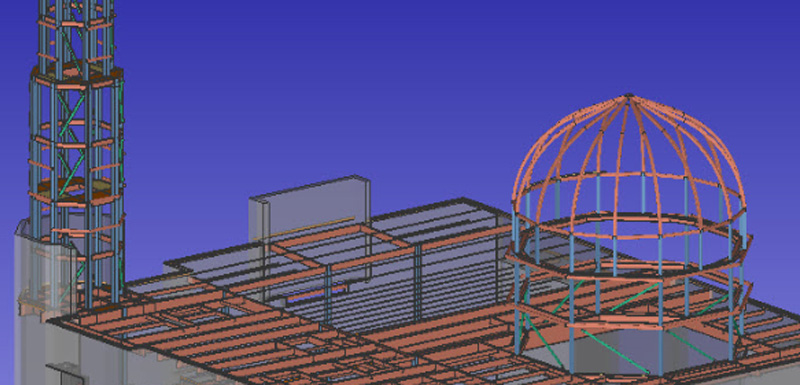

Pittsburgh Steel Group is one of the few fabricators that maintains and supports an in-house detailing department, were most fabricators sub this work out to overseas detailing companies. This provides a superior sense of urgency, commitment to schedules, and accessibility that helps ensure on-time delivery. All detailing / drafting are executed on an integrated 3D modeling SDS 2 software program.

Quality is maintained by ensuring all staff stays current on all A.I.S.C, C.I.S.C, CWB and other common industry codes and specifications.

Pittsburgh Steel Group provides three-dimensional modeling on all projects. This has minimized errors and double entry throughout our production process and allowed better control over project budgets.

.

.

Sub-Contract Erection

PSG uses union certified Ironworkers Erectors to ensure the best possible service when it comes to erecting our product. Our erectors are equipped with the latest safety equipment to complete the job at an accelerated schedule while maintaining the highest level of safety expected by our customers. PSG team works closely with the steel erectors to sequence projects and make sure we are meeting our customer’s needs. Our PM will make multiple visits to the site with the erector to help the customer identify on-site issues that may impact scheduling both before and during erection. Working together as a team we will ensure that the project is completed to our customer’s satisfaction.

.

.

Connection Design

Connections are a critical part of any structural steel project. Pittsburgh Steel Group employee’s the most experienced staff of licensed professional engineers, dedicated to connection design, in the country. Their ability to work closely with the engineer of record for the project provides complete confidence in structural integrity of all delegated connection design.

Engineers use the latest version of SDS-2 3D modeling software to design an unlimited range of connection design solutions accurately and efficiently.

From project beginning to end, Pittsburgh Steel provides the engineering department the support to make any project a success.

.

.

Quality Policy Statement

The quality policy is based on 3 fundamental principles:

a) Pittsburgh Steel Group will keep working hard to maintain customer’s satisfaction and continuing loyalty by professionalism and dedication of the entire PSG team.

b) PSG will continue monitoring and training of all personnel in order to maintain our reputation of proven, experienced professionals in every department, who are recognized throughout the industry for their leadership and commitment to customer satisfaction and who are unsurpassed in their ability to help customers stay on time and within budget.

c) PSG is dedicated to improving the fabrication process to enable exceptional quality, productivity and safety which yield benefits in both human and financial terms for employees and customers.

To ensure that the policy is successfully implemented, staff will be responsible for identifying customer requirements, and ensuring that the correct procedures are followed to meet those requirements. Objectives needed to ensure that the requirements of this policy are met and that continual improvement is maintained in line with the spirit of the policy, will be set, determined and monitored at Management Review. The quality policy principles and objectives will be communicated and available to staff at all times. Training will be an integral part of the strategy to achieve the objectives. Within this Policy we are committed to operating our Company under the disciplines and control of a Quality Management System conforming to the AISC requirements. We are all committed to operating continuously to this standard and we will maintain the necessary Quality Approvals consistent with our customer requirements.

Our Company will constantly review and improve on our services to ensure tasks are completed in the most cost effective and timely manner for the benefit of all our customers. We shall ensure that all our personnel understand and fully implement our Company policy and objectives and are able to perform their duties effectively through an ongoing training and development program. After communication of the quality policy to the employee population, employees at all levels of the organization are expected to fulfill the requirements of this policy in all of their work-related efforts and decisions. Lastly, the quality policy is reviewed at least annually for suitability. Its distribution is controlled because of the possibility that it might change.